Meet Seambit,

IoT at every sewing station

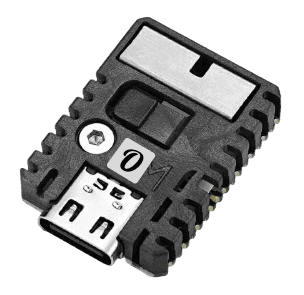

OpenSeam's compact IoT device is called Seambit. It's packed with sensors and onboard intelligence, and it captures the activity of industrial sewing machines continuously, sending real-time data to the cloud, where it becomes actionable insights.

With seambits at every station, you gain complete visibility into your production floors, no matter the sewing machine model.

Seambits install in minutes

Installation process

- Attach - Place seambit on underside of work surface using provided industrial adhesive

- Connect - Plug seambit into existing power source at station

- Activate - Device automatically connects to WiFi and begins streaming data

That's it. No machine modifications. No electrical work. No production interruption.

A mid-sized factory with 500 stations deploys completely in a single shift.

What you need

- Power source at the sewing station (standard electrical outlet)

- Factory WiFi coverage

- Industrial adhesive strips (provided)

How it works

Sensors

Seambits use sensors to detect and capture every needle movement, every burst of sewing activity, every pause. They measure with millisecond accuracy, capturing production reality that human observation simply cannot match.

Connectivity

Each seambit connects to your factory's WiFi network and streams data continuously to OpenSeam's cloud infrastructure. The transmission happens automatically—no manual uploads, no periodic syncing, no data gaps.

Context

For the raw data sent by each seambit to make sense, the system needs factory context. With OpenSeam's analytics tools, it's super easy to assign which seambit is attached to which sewing station, producing which operation for which style, manned by which worker... The context for a production line can be set up in minutes.

AI training

At each seambit, floor supervisors and production managers may use the mobile app to train Tally to accurately understand the actual behavior of each operation assigned. Combined with the sensors data and the factory context, it unlocks the full potential of the AI assistant.

Works with every sewing machine

Universal compatibility

The seambit doesn't integrate with your sewing machines—it observes them. Because we measure physical activity rather than electrical signals or digital interfaces, the device works with any industrial sewing machine regardless of:

- Manufacturer - Brother, Juki, Singer, Pegasus, or any other brand

- Age - From 1960s machines to current models

- Model - Lockstitch, overlock, flatlock, or specialty machines

- Technology level - Mechanical, electronic, or computerized

No compatibility gaps

To date, we haven't encountered an industrial sewing machine we couldn't monitor.

If you use it for garment production, we can measure its activity.

Your entire production floor becomes visible—not just the portion with "compatible" equipment.

The foundation of real-time production intelligence

Seambit devices are the sensor infrastructure that makes OpenSeam's capabilities possible. They're not sold separately—they're part of the complete OpenSeam system that includes:

- Tally AI production assistant for constraint discovery and task routing

- Desktop analytics portal for comprehensive production analysis

- Mobile apps for floor-level real-time notifications

- Digital twin spatial visualization

- Complete historical data retention and trending

The seambit captures reality. The OpenSeam platform turns that reality into actionable intelligence.